Shoes

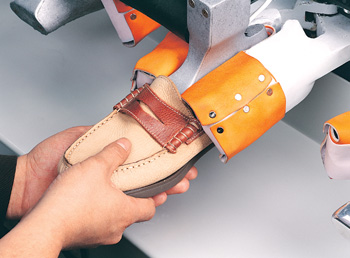

Setting Machine (to setting the hollow: instep, backpart and both

sides of the shoes) |

|

|

MACHINE CHARACTERISTICS |

This

Electro-pneumatic machine has been design with 2 or 4 horizontal

moulds and with silicon cushions, to setting the sides of the

shoes.

These

moulds can be made with heat system and cold system.

|

|

1.995

Kb 1.995

Kb |

| |

| Modularity |

|

The

cushions are covered with leather and Teflon to avoid damages or

dirtiness. They press to the both sides of the moulds with a total

adaptability |

| |

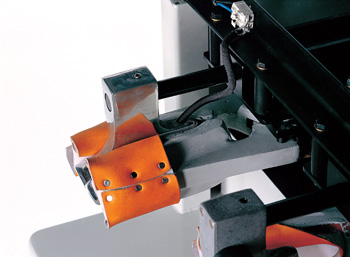

Ergonomic

operator position to work easily with big productions.

With

the 4 posts, one operator can setting two pairs at time.

The

V-93 machine has been designed to fix the shoe form before the

finish packed to guarantee the same form in all production.

|

|

|

| Security

|

| |

Our

machines design have all Safety Prevention European Normative. |

|

|

| Conformed |

|

|

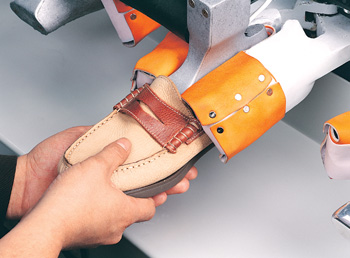

| With

this machine, you will present to the consumers a correctly formed

shoe, to guarantee the quality, so to increase the sales |

Connected

to the machine, there is a microprocessor control, a temperature

and press control to guarantee the quality level with big productions.

The operator decide the best regulation to every shoe, obtaining

an optimum output. |

|

| |

Four

moulds |

| Electric

connection |

220v

50/60 Hz |

| Max.

Pneumatic Connection |

7

BAR |

| Max.

Electric consumption |

0’4

Kw / H |

| Work

average power consumption |

0’1

Kw / H |

| Air

Consumption |

9

Liters |

| Work

cycle |

Automatic |

| Timer

cycle |

0

– 60 seconds |

| Moulds

temperature |

-30ºC

a 200ºC |

| Production

(Aprox) |

120

Pairs / Hour |

| Net

weight (Aprox) |

265

Kgs |

| Gross

weight (Aprox) |

300

Kgs |

| |

|

| Dimensiones: |

|

| High

|

1.120

mm |

| Width |

1.018

mm |

| Deep

|

685

mm |

|